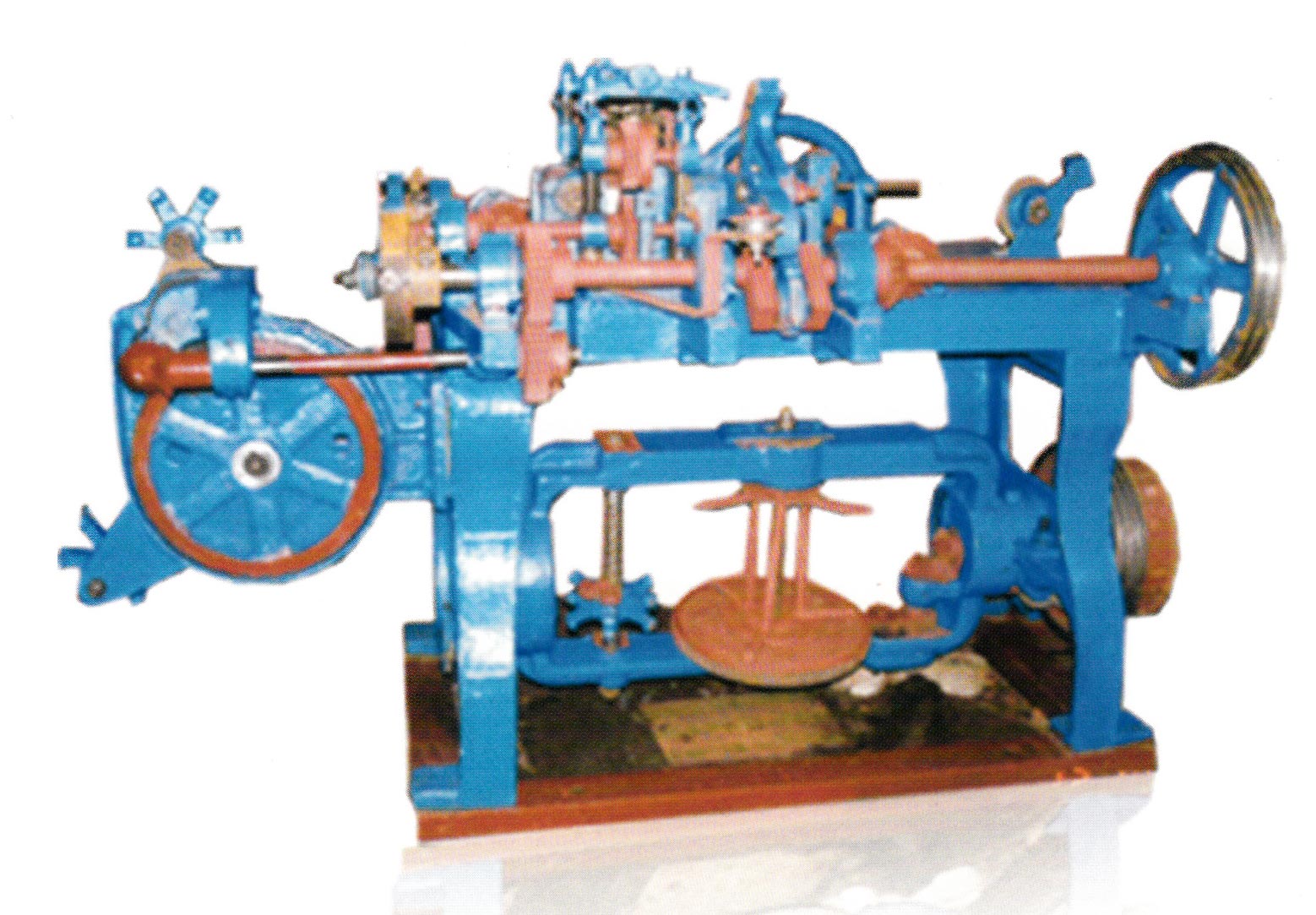

All common types of barbed wire with 2 & 4 points and unidirectional twist e.g. Glidden, IOWA etc. can be produced on the BSMW CBI. The machine can also be used for three ply barbed wire. The range of application of the CBI is wide and the machine can be reset quickly and is simple to operate.

The horizontal and easily accessible arrangement of the tooling facilitates quick re-setting to other wire gauges and different types of barbed wire. Since shafts run in anti-friction bearings, very little wear takes place despite the high output, and maintenance has been reduced to a minimum.

The full reel can be quickly removed from the coiling frame. Due to the strong design of the frame, rolls upto 40-50 kg weight may be produced.

| SIZE OF WIRE | SWG 12-14 |

| OUTPUT | 1000 Kgs using 12 SWG in 8 hours running shift 700 Kgs using 14 SWG in 8 hours running shift |

| POWER REQUIRED | 5 HP |

| FLOOR SPACING (in feet) | 8'x3'x6' |

| WEIGHT (approx) | 1500 kgs |

The horizontal and easily accessible arrangement of the tooling facilitates quick re-setting to other wire gaugcs and different types of barbed wire. Since shafts run in anti-friction bearings, very little wear takes place despite the high output, and maintenance has been reduced to a minimum.

The full reel can be quickly removed from the coiling frame. Due to the strong design of the frame, rolls upto 40-50 kg weight may be produced.